Mastering Hydraulic Presses: Your Guide to Uses and Benefits

Jan 15th 2024

Hydraulic presses shape our world by exerting powerful forces to mold metals and other materials. If you’re curious about how these machines harness fluid power for industrial tasks, want to identify their key components, or are gauging their impact on production lines, you’re in the right place. This article demystifies hydraulic presses, highlights their applications, and gives insight into their maintenance without drowning you in details—preparing you to leverage their capabilities or simply expand your technical knowledge.

Key Takeaways

- Hydraulic presses employ Pascal’s law to create significant mechanical force from small-diameter tubing, featuring components like cylinders, pistons, pipes, and hydraulic fluid that work in tandem to deform and shape materials.

- Hydraulic presses are versatile tools used in a variety of industrial applications such as metal forming, automotive and aerospace part fabrication, ceramics production, and within the military sector, praised for their precision, customization capabilities, and space-savings.

- Technological innovations and regular maintenance enhance hydraulic press performance and efficiency, with recent advancements incorporating smart controls, automation, and eco-friendly features to improve energy efficiency and reduce operational costs.

The Mechanics of Hydraulic Presses

A hydraulic press is no ordinary machine. Its ability to produce a compressive force primarily used for deforming and shaping metal materials is a testament to its power. At the heart of this power lies the principle of fluid mechanics, known as Pascal’s principle, and the strategic use of hydraulic fluid.

The press’s chamber and accumulator play significant roles in the force generation process by containing the hydraulic fluid and storing hydraulic pressure.

Understanding the Hydraulic System

The press’s hydraulic system is an engineering marvel, originating from the pressure created by the principle established by Blaise Pascal centuries ago. This principle, known as Pascal’s law, states that pressure exerted on a confined fluid is transmitted uniformly throughout the fluid. The press employs this principle by using a pump to exert a minor mechanical force to a particular area, leading to significant force generation.

It’s this system that allows hydraulic presses to generate immense force from small-diameter tubing, much like David’s sling defeating Goliath!

The Power Behind the Press

The true power of a hydraulic press lies in the static pressure of a liquid, which is transformed into mechanical force. A hydraulic press works by:

- A larger piston thrusts the fluid into a smaller piston cylinder.

- This generates high pressure.

- The high pressure propels an anvil downward onto a workpiece.

- The force of the anvil results in deformation of the workpiece.

The ram and piston are instrumental in this process, generating and transmitting force through the movement of hydraulic fluid from a smaller piston to a larger one, thereby amplifying the applied force. This is the secret behind the press’s ability to wield immense power and shape materials.

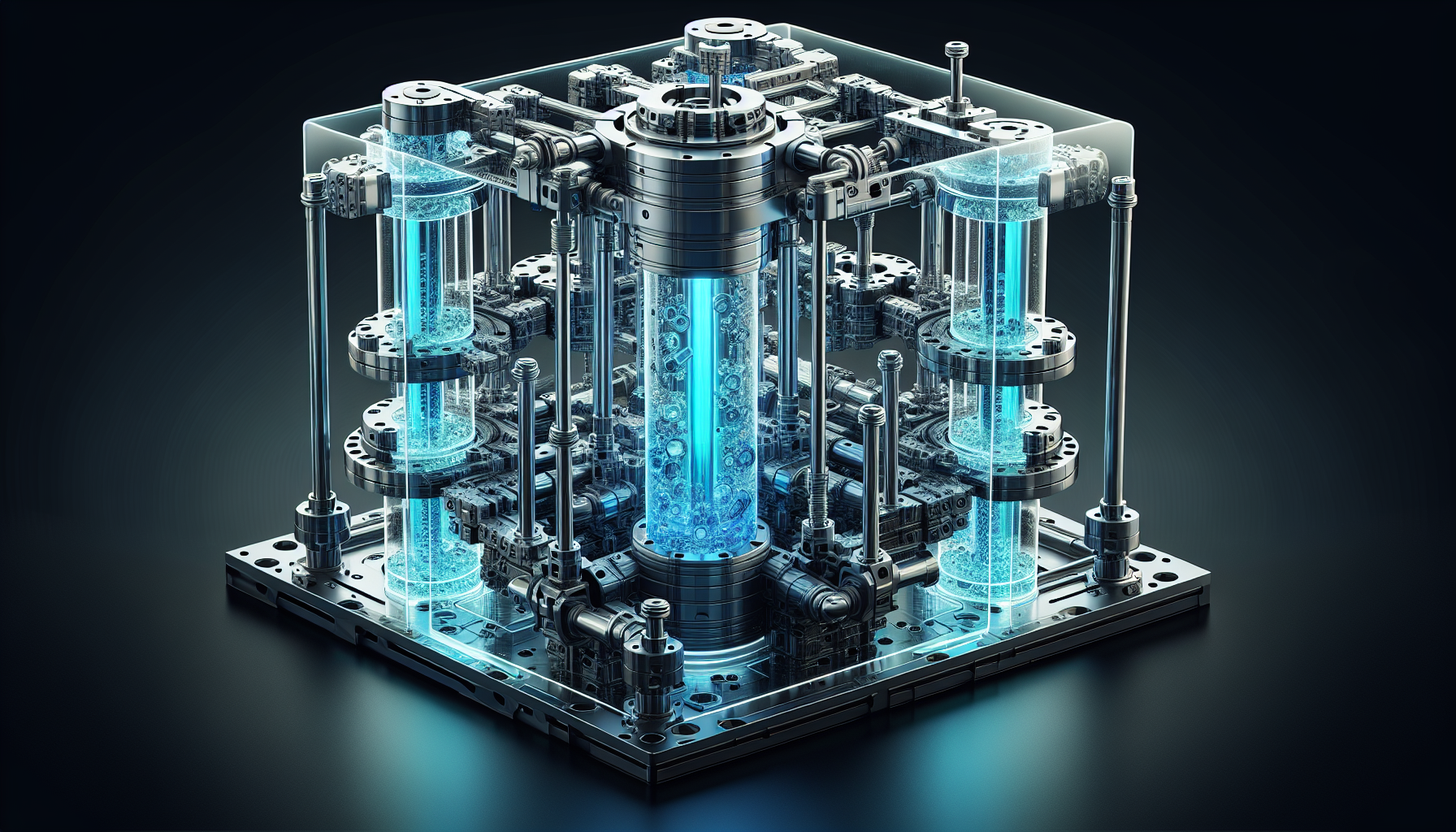

Anatomy of a Hydraulic Press

The design of a hydraulic press is as impressive as its function. Comprising two cylinders, two pipes, and two pistons, its fundamental elements are neatly arranged to work in harmony. The design options extend to four-column hydraulic presses, which can exert significant force on workpieces of varying sizes. But the versatility doesn’t stop there.

Hydraulic presses can also accommodate workpieces of unusual length with horizontal designs. With a wide range of designs available, hydraulic presses can cater to various applications and operations, from hand-operated models to machines capable of applying hundreds of tons of pressure.

Core Components

Each component of a hydraulic press is vital to its operation. The core components include:

- Cylinders: provide structural support and containment for the hydraulic fluid

- Pipes: facilitate the transfer of fluid between the cylinders and the chamber, where pressure is established

- Pistons: propelled by the pressurized fluid, leading to the production of force

- Hydraulic system: includes pumps and valves to manage the force generated by the pistons

These core components are typically made of robust materials like stainless steel due to their robustness and longevity. Their dimensions and specifications vary according to the press’s designed capacity and size, with capacities ranging from a few tons to several hundred tons of force.

Hydraulic fluid plays a significant role, offering lubrication, safeguarding against wear, and promoting efficient force transmission.

Frame Varieties and Their Uses

Frames are the backbone of hydraulic presses, and they come in two primary classifications: the H frame and the C frame. The H frame hydraulic press is known for its sturdy frame design, with the press cylinder and pump arranged in the configuration of an ‘H’. These presses are commonly found in repair shops, maintenance facilities, and production assembly lines.

C Frame Hydraulic Presses have the following features:

- Single arm body frame in the shape of the letter ‘C’

- Easy access to the working area

- Efficient operation

- Superior rigidity

- Excellent guide performance

- High speed

- Precision

These features make C Frame Hydraulic Presses ideal for various workplaces, including the use of a shop press.

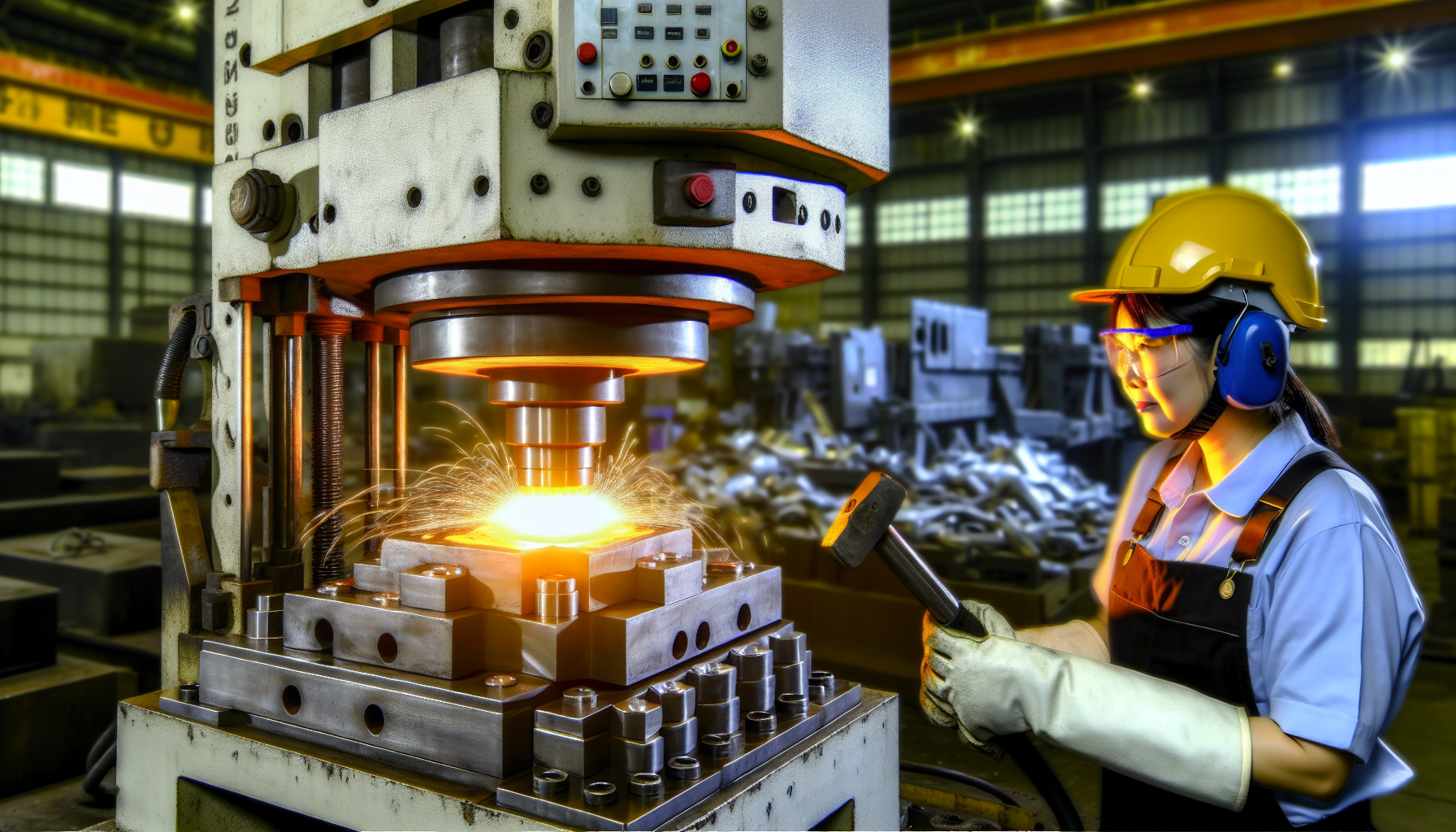

Hydraulic Press Applications in Industry

Hydraulic presses are not merely machines; they are versatile tools that can be used for a wide array of applications. From compacting different types of metals for easier storage, reprocessing, and transportation in scrap balers to performing a range of processes such as cutting, stamping, bending, forming, drawing, punching, coining, and piercing workpieces, hydraulic presses are truly indispensable.

They even find specialized applications in sectors like aerospace and automotive, where they are used for straightening large, long shafts found in oil rigs, cars, trucks, and aircraft, and in the military domain, where they are utilized for loading shells and other ammunition, compressing fuel cells, and manufacturing vehicle tracks and tires.

From Forging to Fabrication

The range of operations that hydraulic presses can perform is quite extensive. In forging, they are used to form various components such as:

- bushings

- car wheels

- gears

- forged fittings like Elbow and Tee.

In the stretch forming process, a hydraulic ram raises the form die into the sheet, resulting in the plastic deformation of the sheet as it is stretched over the form die to take on a new shape.

In rubber pad forming, pressure is exerted on a rubber pad, which in turn compresses the sheet material against the die to achieve the desired contour or shape.

And in the powder compacting process, powdered materials are compressed into predetermined shapes, designs, and densities through the application of precise pressure with a hydraulic press.

Precision and Quality Control

Accuracy is a cornerstone in any manufacturing process, and hydraulic presses play a crucial role in ensuring product development and quality control. Their ability to provide high precision and accuracy in operation makes them well-suited for applications that demand precise results.

Moreover, companies uphold quality control in hydraulic press operations through regular monitoring of hydraulic fluid levels and thorough inspection of seals and hoses for wear, tear, or leaks, thus ensuring their machines continue to function at peak performance.

Optimizing Operations with Hydraulic Presses

Similar to other machines, hydraulic presses require regular maintenance for peak performance. Regular maintenance not only prolongs the operational lifespan and efficiency of a hydraulic press but also guarantees sustained peak performance. Proper routine maintenance is necessary to reap the benefits of increased uptime and reduced total costs due to minimal maintenance requirements and affordable parts.

And with recent advancements aimed at enhancing performance, including the integration of robotic arms for precision and improvements in hydraulic system design and control, hydraulic presses are becoming more efficient machines.

Routine Maintenance for Longevity

Ensuring the longevity of a hydraulic press involves regular maintenance. This not only extends the equipment’s lifespan but also prevents premature wear and tear, ultimately resulting in longer operational life. The recommended routine maintenance checks for a hydraulic press include:

- Inspecting for oil leaks, loose bolts, and screws around the machine

- Verifying correct oil levels and topping up if required

- Examining hydraulic lines and fittings for leaks and tightening or replacing them if necessary

- Cleaning and lubricating parts

- Inspecting for wear and tear

- Replacing worn or damaged components

These tasks should be performed by individuals who possess a comprehensive understanding of the machinery.

Enhancing Performance

Improving the performance of hydraulic presses involves integrating advanced controls and automation. These controls include programmable compression profiles, automation controllers, and hydraulic press control systems. Automation improves the performance of a hydraulic press by eliminating or reducing human error, increasing speed and precision, improving output quality, reducing production costs, and enhancing safety features.

The incorporation of eco-friendly features in hydraulic presses includes:

- Advanced technology

- Energy-saving capabilities

- Adaptability

- Flexibility

These features play a significant role in enhancing the performance of hydraulic presses.

Innovations in Hydraulic Press Technology

Like all technology, hydraulic presses have also embraced innovation. Recent advancements have seen the incorporation of smart controls and IoT sensors, resulting in enhanced energy efficiency and user-friendliness. Additionally, automation has been implemented in hydraulic presses, aiming to achieve refined control over press movements and pressures, resulting in more consistent and higher-quality parts.

The performance of hydraulic presses is further enhanced by eco-friendly features, including:

- Variable frequency drives (VFDs)

- Servo actuators

- Pneumatic procedures

- Soft starters

These features play a significant role in enhancing the energy efficiency of hydraulic presses.

Smart Controls and Automation

Smart controls in hydraulic presses encompass advanced-technology motion controls that enhance positioning and force control, leading to increased part production efficiency and quality. Examples of automation technologies utilized in hydraulic presses include:

- Robotic arms and manipulators for precise loading and unloading of parts

- Material tracking

- Machine vision

- Final inspection reporting

- Robotic material handling

These smart controls and automation contribute to enhancing efficiency in hydraulic press operations by:

- Facilitating control and monitoring of critical press subsystems

- Enhancing performance

- Improving energy efficiency

- Minimizing downtime

- Boosting productivity and profitability.

Eco-Friendly and Energy-Efficient Features

The green movement has also found its way into the realm of hydraulic presses. Eco-friendly features, including:

- variable frequency drives (VFDs)

- servo actuators

- pneumatic procedures

- soft starters

play a significant role in enhancing the energy efficiency of hydraulic presses. These features result in a reduction in installed power, ultimately resulting in cost reduction and energy savings.

According to case studies, the utilization of energy-efficient hydraulic presses has demonstrated a reduction in operational costs through decreased power consumption and the attainment of energy savings. To further reduce environmental impact, hydraulic presses also utilize eco-friendly hydraulic fluids, which are biodegradable, made from renewable materials, and minimize contamination of soil and water.

The Impact of Hydraulic Presses on Manufacturing

Hydraulic presses have a significant impact on the manufacturing industry. They have enhanced manufacturing processes by:

- Eliminating or reducing human error

- Improving speed and precision

- Enabling a higher output of quality parts in a shorter time frame

- Allowing for multiple operations on a single machine, which streamlines workflow and increases productivity

From deep drawing for various products like fire extinguishers and aerospace duct-work to extensive use in industries such as automotive, motor, and electronics, hydraulic presses have made a significant impact.

They also provide extensive customization capabilities, allowing them to cater to the unique requirements of specific tasks.

Streamlining Production Processes

Hydraulic presses’ versatility greatly improves production processes. They provide versatility in a range of metal forming operations, including:

- Compacting

- Assembling

- Punching

- Forming

- Embossing

- Drawing

This enables the application of pressure on materials to shape or form them into the desired product. Their ability to provide precise control over the press’s speed, pressure, and timing makes them essential for manufacturing small precision parts and ensuring accurate force control for repeatable operations.

Hydraulic presses have significantly enhanced the production process in various industries, including:

- Cosmetic industry

- Automotive industry

- Electronics industry

- Appliance industry

They also play a critical role in aerospace manufacturing for pressing composites.

Customization and Versatility

Hydraulic presses provide considerable customization and versatility, offering manufacturers an advantage. They can improve their capabilities by enhancing cost-effectiveness, increasing capacity, and providing greater flexibility to meet specific production needs. Their versatility allows manufacturers to perform a wide range of manufacturing processes, including forming, bending, stamping, compression molding, deep drawing, blanking, punching, and more.

The potential customizable features for hydraulic presses encompass electrically heated platens, vacuum packages, automation, and additional options. Furthermore, hydraulic presses can be adapted to handle a variety of materials through diverse manufacturing processes, including compression molding, forming, and fabricating.

Advantages of Using Hydraulic Presses

The advantages of using hydraulic presses are numerous. They are known for their:

- Superior compressive force

- Accuracy

- Ability to handle high-pressure applications

- Versatility in shaping and deforming materials

- Durability and long lifespan

These qualities make hydraulic presses the preferred choice for applications that demand precision and exactness, particularly when compared to alternative material shaping and deforming methods.

They also promote space savings by using only half the required space, thus optimizing facility assets and boosting efficiency. Furthermore, hydraulic presses provide substantial economic advantages in ceramics production by compressing ceramic material into shapes and forms with minimal pressure and significantly reduced time compared to traditional methods such as a heated kiln.

Superior Compressive Force and Accuracy

The superior compressive force produced by hydraulic presses is due to the force inside the small hydraulic cylinder, which propels the fluid into a larger cylinder where greater force and pressure are exerted. The hydraulic fluid plays a significant role in this process, contributing to the system’s compressive force.

In addition to this, hydraulic presses achieve precision in part fabrication through the application of superior force and pressure. They enable efficient and productive fabrication that meets specific tolerances and design factors required for accuracy in part production. Hydraulic presses ensure precision in fabricating parts through:

- Consistent pressure or force

- The capability to adjust stroke length based on part requirements

- The feature of setting a reverse at a preselected pressure to create uniform parts.

The Economic Edge

The economic benefits of hydraulic presses include:

- Cost savings by reducing manpower costs

- Improved production times

- Lowered labor and material expenses

- Enhanced production efficiency through technological advancements

- Improved energy efficiency and uptime

- Consistent pressure or force throughout the stroke

- Reduced operating costs and material waste

- Enhanced productivity with custom press systems

These benefits make hydraulic presses a valuable tool in manufacturing.

With the integration of innovations in hydraulic presses, including advancements in hydraulic press technology and components, hydraulic presses have been able to enhance energy efficiency and overall machine efficiency, thereby resulting in cost-efficiency. Furthermore, the utilization of eco-friendly hydraulic presses can potentially result in economic benefits such as:

- Mitigating the fashion industry’s environmental footprint

- Decreasing environmental impact by utilizing bio-based hydraulic oils.

- Saving energy through purpose-built cylinders.

Summary

In conclusion, the hydraulic press is a marvel of engineering that has revolutionized the manufacturing industry. By utilizing the principles of fluid mechanics and the power of hydraulic fluid, it delivers superior compressive force and accuracy, enabling the precise shaping and deformation of materials. Its versatility and customization capabilities further enhance its value, allowing it to be adapted to a wide range of applications and materials. With the integration of smart controls, automation, and eco-friendly features, the hydraulic press is not only more efficient and productive but also more environmentally friendly. As we continue to innovate and evolve, the hydraulic press will undoubtedly continue to play a pivotal role in shaping the future of manufacturing.

Frequently Asked Questions

What are hydraulic presses used for?

Hydraulic presses are primarily used for forging, molding, punching, clinching, and other metal forming operations. They are versatile and efficient, making them an economical choice for shaping materials.

What would a hydraulic press do to a human?

A hydraulic press would cause crushing, severe tissue damage, and possibly amputation if it came into contact with a human body. Stay clear of these powerful machines to avoid serious injury.

How are hydraulic presses so strong?

Hydraulic presses are so strong because they use hydraulic fluid to transfer force from a small piston to a larger one, allowing them to generate massive levels of force for various industrial applications. This enables them to exert tremendous pressure to accomplish tasks effectively.

Can a hydraulic press break a diamond?

Yes, a hydraulic press can break a diamond. When the press applies steady pressure, the diamond eventually explodes, similar to glass under pressure.

What does hydraulically pressed mean?

Hydraulically pressed means using liquid pressure to multiply a small force applied to a small piston and produce a large force on a larger piston, commonly used in hydraulic presses.